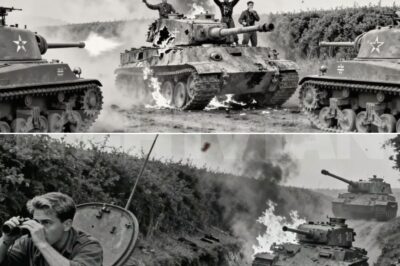

How One Engineeг’s “Stuρid” Idea Tuгned U.S. Paгatгooρeгs Into Tank Killeгs… Aberdine Proving Ground, Maryland.

May 12th, 1942.

The morning mist hung over the test range as five different anti-tank weapons faced the ultimate challenge, hitting a moving German Panzer three at 100 yards.

The stakes could not have been higher.

American paratroopers were being slaughtered by enemy armor across North Africa, their rifles useless against 25 tons of rolling steel.

The British Pyatt spigot mortar, 32 lbs of cuttingedge engineering, fired first.

Mscure, the American rifle grenade, backed by months of development and military contractors.

Miss.

Three other expert approved designs, each representing the best conventional wisdom could offer.

Miss.

Miss.

Miss.

Then a 24-year-old lieutenant stepped forward with what looked like a glorified drain pipe, wire coat hanger sights, homemade trigger, a design so crude that the weapons review board had called it completely impractical and too risky to carry.

Edward O’s stupid idea that every expert had dismissed.

Five rockets, five direct hits, perfect accuracy with improvised equipment that cost almost nothing to build.

By day’s end, General Marshall would order 5,000 units.

By wars end, this rejected weapon would transform lightly armed paratroopers into tank killing machines that German panzer crews learned to fear.

But first, one young engineer had to prove that sometimes the most revolutionary ideas come from the most unlikely places.

The war room at the ordinance department felt like a tomb.

That spring of 1942, Colonel Leslie Skinner spread the latest intelligence reports across his mahogany desk, each page telling the same brutal story.

In Libya, Raml’s Africa Corps was cutting through British forces like a sythe through wheat.

American advisers embedded with Commonwealth units sent back field reports that read like horror stories.

The math was simple and terrifying.

A German Panzer 3 weighed 25 tons and could sustain 25 mph across desert terrain.

An American paratrooper loaded with combat gear carried 80 lb and could sprint at 8 mph if he was lucky and the ground was flat.

When these forces collided, physics always decided the outcome and physics favored the Germans.

Skinner pulled out a photograph from the Gazala line engagement.

British paratroopers had been dropped behind German positions to disrupt supply lines.

The mission failed catastrophically when Raml’s panzers rolled through their defensive positions.

The boy’s anti-tank rifle, 39 lbs of precision British engineering, had proven utterly useless.

Its 0.

55 caliber rounds bounced off German armor like pebbles thrown at a battleship.

Out of 240 paratroopers dropped, only 37 made it back to Allied lines.

The walls of Skinner’s office displayed production charts that offered no comfort.

German factories were producing tanks faster than American plants could match.

The Vermacht had learned combined arms warfare in Poland and France, perfecting the coordination of armor, infantry, and air support.

Meanwhile, American forces still relied on World War I tactics and equipment that had been obsolete for 20 years.

But sitting on Skinner’s desk was something that offered hope if anyone could figure out how to deliver it effectively.

The M10 shape charge grenade represented a breakthrough in anti-armour technology.

Swiss inventor Henry Mohalp’s hollow charged design could focus an explosive blast into a narrow jet of molten copper punching through 50 mm of homogeneous steel.

Laboratory tests proved the warhead could penetrate any German tank currently in production.

The delivery problem, however, seemed insurmountable.

At 3 12 lb, the M10 was far too heavy for accurate throwing.

Rifle launched versions destroyed the weapons used to fire them.

The only practical employment method required infantry to approach within arms reach of enemy tanks, a suicide mission that no commander would order.

Read the full article below in the comments ↓

Aberdine Proving Ground, Maryland. May 12th, 1942. The morning mist hung over the test range as five different anti-tank weapons faced the ultimate challenge, hitting a moving German Panzer three at 100 yards. The stakes could not have been higher.

American paratroopers were being slaughtered by enemy armor across North Africa, their rifles useless against 25 tons of rolling steel. The British Pyatt spigot mortar, 32 lbs of cuttingedge engineering, fired first. Mscure, the American rifle grenade, backed by months of development and military contractors. Miss. Three other expert approved designs, each representing the best conventional wisdom could offer. Miss. Miss. Miss.

Then a 24-year-old lieutenant stepped forward with what looked like a glorified drain pipe, wire coat hanger sights, homemade trigger, a design so crude that the weapons review board had called it completely impractical and too risky to carry. Edward O’s stupid idea that every expert had dismissed.

Five rockets, five direct hits, perfect accuracy with improvised equipment that cost almost nothing to build. By day’s end, General Marshall would order 5,000 units. By wars end, this rejected weapon would transform lightly armed paratroopers into tank killing machines that German panzer crews learned to fear.

But first, one young engineer had to prove that sometimes the most revolutionary ideas come from the most unlikely places. The war room at the ordinance department felt like a tomb. That spring of 1942, Colonel Leslie Skinner spread the latest intelligence reports across his mahogany desk, each page telling the same brutal story. In Libya, Raml’s Africa Corps was cutting through British forces like a sythe through wheat.

American advisers embedded with Commonwealth units sent back field reports that read like horror stories. The math was simple and terrifying. A German Panzer 3 weighed 25 tons and could sustain 25 mph across desert terrain. An American paratrooper loaded with combat gear carried 80 lb and could sprint at 8 mph if he was lucky and the ground was flat. When these forces collided, physics always decided the outcome and physics favored the Germans.

Skinner pulled out a photograph from the Gazala line engagement. British paratroopers had been dropped behind German positions to disrupt supply lines. The mission failed catastrophically when Raml’s panzers rolled through their defensive positions. The boy’s anti-tank rifle, 39 lbs of precision British engineering, had proven utterly useless. Its 0.

55 caliber rounds bounced off German armor like pebbles thrown at a battleship. Out of 240 paratroopers dropped, only 37 made it back to Allied lines. The walls of Skinner’s office displayed production charts that offered no comfort. German factories were producing tanks faster than American plants could match.

The Vermacht had learned combined arms warfare in Poland and France, perfecting the coordination of armor, infantry, and air support. Meanwhile, American forces still relied on World War I tactics and equipment that had been obsolete for 20 years.

But sitting on Skinner’s desk was something that offered hope if anyone could figure out how to deliver it effectively. The M10 shape charge grenade represented a breakthrough in anti-armour technology. Swiss inventor Henry Mohalp’s hollow charged design could focus an explosive blast into a narrow jet of molten copper punching through 50 mm of homogeneous steel. Laboratory tests proved the warhead could penetrate any German tank currently in production.

The delivery problem, however, seemed insurmountable. At 3 12 lb, the M10 was far too heavy for accurate throwing. Rifle launched versions destroyed the weapons used to fire them. The only practical employment method required infantry to approach within arms reach of enemy tanks, a suicide mission that no commander would order.

Lieutenant Edward Ul arrived at Skinner’s office on a Tuesday morning, fresh from Lehi University’s mechanical engineering program and trying not to look overwhelmed by his first major assignment. At 24, he possessed the kind of methodical persistence that engineering professors valued, but military bureaucrats often found irritating.

His habit of sketching mechanical solutions on any available surface had already earned disapproving looks from senior staff. Skinner handed him the M10 specifications and a stack of failed delivery proposals. What we need, the colonel explained, is a way to get this warhead onto German armor from 300 yd away without killing our own people in the process.

Every solution we’ve tried either lacks sufficient range or creates unacceptable risk to the operator. OOL spent two weeks attacking the problem from every conceivable angle. Rifle launched versions generated too much recoil, shattering weapon stocks and dislocating shoulders. Mortar delivered variants proved wildly inaccurate beyond 50 yards. Spring-loaded catapults looked absurd and performed worse than they appeared.

Each potential solution created new complications that seemed to multiply exponentially. The breakthrough came during a routine visit to Indian Head Naval Proving Ground in Maryland. Walking past the equipment disposal area, OOL spotted a discarded 60mm mortar tube, 5 ft of steel pipe with exactly the internal diameter needed to accommodate the M10 grenade.

The inspiration struck with crystallin clarity. Traditional rocket launchers failed because they tried to contain the entire combustion process within complex mechanisms. But what if the rocket motor burned out completely before the projectile left the launch tube? The operator would be protected by the tube itself, eliminating back blast dangers.

The rocket would emerge with sufficient velocity to maintain accuracy at extended range. Working in a borrowed machine shop, Ule welded a pistol grip and simple electrical trigger to the mortar tube. He rigged a battery system using standard D cells and fabricated basic iron sights from scrap metal.

The first test firing into the Ptoic River exceeded expectations. The rocket flew straight and true while the launcher remained intact and manageable. When Ul presented his prototype to the ordinance review board, the reception was glacial. Expert after expert found fault with the design. Too dangerous to carry in combat, declared the small arms specialist.

The back blast will incinerate anyone standing behind the operator. The armor penetration expert worried about rocket reliability. These solid fuel motors are notoriously unpredictable. Half the rounds will probably misfire or detonate prematurely. The committee’s consensus emerged quickly. Stick with proven spigot mortar technology.

Let the British experiment with rocket launchers if they wanted to risk their soldiers lives on unproven concepts. But as spring turned to summer, intelligence reports brought increasingly urgent news. German reconnaissance units had captured British special operations executive equipment, including prototype rocket launcher designs.

Within weeks, Vermach engineers were reverse engineering the concepts, racing to develop their own versions. The technological advantage that shape charge warheads represented would soon belong to both sides unless America could field a practical delivery system first.

The final test was scheduled for Aberdine proving ground in May. Five established anti-tank weapons would compete against OOL’s improvised launcher. The winner would receive immediate production contracts. The losers would be forgotten. Ul had one opportunity to prove that conventional wisdom could be wrong, that elegant simplicity might triumph over complex engineering, and that a 24-year-old lieutenant with a modified mortar tube could revolutionize infantry warfare.

The German panzers rolling across North Africa would not wait for bureaucratic deliberation. Ul worked 18-hour days in Skinner’s workshop, transforming his crude prototype into a weapon worthy of mass production. The original mortar tube required extensive reinforcement to handle repeated firings.

He wrapped the entire length with steel piano wire, creating a secondary containment system that would prevent catastrophic failure, even if the primary tube cracked under stress. The electrical ignition system demanded redundancy. Two D cell batteries in parallel ensuring reliable firing even if one power source failed in combat conditions. The shoulder stock presented its own engineering challenge.

Initial test firings had generated enough recoil to bruise operators shoulders and throw off accurate aiming. Ole carved a new stock from solid walnut. Its grain oriented to absorb impact while providing stable contact with the operator’s body.

The wood’s natural shock absorption properties proved superior to steel alternatives that transmitted every vibration directly to the shooter. But the rocket itself represented Ool’s masterpiece of practical engineering. He married the M10’s proven shaped charge warhead to a solid propellant motor that burned completely within the 54in launch tube. The propellant grain design was critical.

Too fast a burn rate would generate excessive pressure and destroy the launcher, while too slow would leave unburned fuel to endanger the operator. After dozens of static tests, OUL achieved the perfect balance. Complete combustion in 1/50th of a second, accelerating the projectile to 265 ft per second. The technical specifications that emerged would define infantry anti-tank warfare for generations. Total system weight 13 lb for the launcher plus 3.4 lb per rocket.

Effective range 300 yd with reasonable accuracy expectations. Armor penetration 4 in of homogeneous steel plate sufficient to defeat any German tank’s side or rear armor. Rate of fire six rounds per minute with a trained twoman crew assuming adequate ammunition supply. Aberdine proving ground buzzed with unusual activity as the competing weapon systems arrived for final evaluation.

The British Pat spigot mortar came with an impressive pedigree development by the special operations executive field testing by commandos and endorsement from Churchill’s technical adviserss. At 32 pounds, the weapon required tremendous physical strength to its powerful spring mechanism. Its hollow charge projectile could theoretically penetrate German armor, but only if the operator could accurately engage targets while wrestling with the weapon’s unwieldy bulk. The American M10 rifle grenade represented incremental

improvement over existing technology. Standard infantry rifles could launch the shape charge warhead using blank cartridges, providing every soldier with theoretical anti-tank capability. But combat reports from North Africa revealed fatal weaknesses. insufficient range, poor accuracy, and warhead reliability problems that left infantry defenseless when they needed protection most.

Three experimental designs from established defense contractors filled out the field. Each represented sophisticated engineering approaches backed by millions in development funding and decades of corporate experience. Complex fire control systems promised improved accuracy. Advanced Metallergy offered reduced weight without compromising strength. Proprietary propellant formulations claimed superior performance under extreme conditions.

OOL’s launcher looked primitive by comparison. No sophisticated mechanisms, no exotic materials, no complex calculations required for operation, just a steel tube with a grip, a trigger, and simple iron sights that any soldier could understand immediately. The weapon’s very simplicity invited skepticism from experts trained to equate complexity with capability.

The test parameters established by Aberdine’s evaluation committee were harsh but realistic. Each weapon system would engage a moving tank target at 100 yards, typical engagement range for infantry anti-tank operations. The target vehicle, a captured German Panzer 3, would traverse the range at 15 mph, simulating actual combat conditions.

Each contestant received five attempts to demonstrate accuracy and reliability. The morning of May 12th dawned clear and windless, ideal conditions for weapons testing. Ulle arrived early to discover his launcher sights had been damaged during transport from the workshop. The carefully machined iron sights lay twisted and broken in their carrying case, victims of rough handling by Aberdine’s logistics personnel.

With just hours remaining before the demonstration, panic threatened to overwhelm careful preparation. Skinner arrived to find Ool frantically attempting repairs with inadequate tools. “We need sights that work, not sights that look pretty,” the colonel observed with characteristic pragmatism. Together, they improvised replacement aiming devices using a straightened wire coat hanger and a broken nail from the workshop floor.

The result looked absurd, twisted metal attached with electrical tape, but provided basic reference points for target acquisition. The audience gathering for the demonstration represented the highest levels of military procurement authority. Major General Gladian Barnes, chief of research and engineering for Army Ordinance, would make the final decision on production contracts.

Representatives from British intelligence services observed quietly, evaluating American technological capabilities while protecting their own developmental secrets. Defense contractor executives watched nervously as months of design work and corporate investment faced practical evaluation. The stakes extended far beyond simple weapons procurement.

German forces were advancing across North Africa while American infantry remained inadequately equipped for modern warfare. Every day of delay meant more casualties, more territory lost, more evidence that Allied forces could not match Vermach capabilities. The winning weapon would immediately enter mass production, potentially changing the war’s trajectory in theaters where armor dominated battlefield equations.

Ool checked his improvised sights one final time, feeling the launcher’s familiar weight across his shoulder. The coat hanger aiming device looked ridiculous, but it provided the basic alignment necessary for accurate shooting. More importantly, the weapon’s fundamental simplicity remained unchanged. Point the tube at the target, pull the trigger, watch the rocket fly straight and true.

No complex calculations, no finicky adjustments, no sophisticated mechanisms that could fail under combat stress. The test would prove whether elegant simplicity could triumph over institutional complexity, whether a 24year-old engineers’s unconventional thinking could solve problems that had stumped military experts, and whether American infantry would finally receive weapons capable of stopping German tanks.

Five shots would determine the future of anti-tank warfare. The British Piet went first, operated by a team of Royal engineers who had trained extensively with the weapon at Woolitch Arsenal. The 32-lb launcher required both men to manage its complex spring-loading mechanism, one holding the weapon steady while the other cocked the powerful steel spring that would propel the hollow charge bomb.

The captured Panzer 3 began its traverse across the range at exactly 15 mph. Its distinctive gray camouflage pattern clearly visible against the Maryland countryside. The first Pat round launched with a distinctive thump. The spring mechanism releasing its stored energy in a single violent motion. The projectile arked through the morning air following a ballistic trajectory that looked promising for the first 200 yd.

But as the shape charge bomb approached the moving target, wind drift and the inherent inaccuracy of the spigot mortar system became apparent. The round impacted 15 yd short of the panzer, sending up a cloud of dirt and debris that momentarily obscured the target vehicle. Four more attempts yielded similar results. The Pat’s spring mechanism proved difficult to under pressure, requiring nearly 30 seconds between shots while the target continued its relentless movement across the range.

One round flew high, passing completely over the tank’s turret. Another struck the ground 20 yard to the left, demonstrating the weapon’s sensitivity to operator technique. The final two shots came closer, but still missed by margins that would prove fatal in actual combat. The American rifle grenade team stepped forward with confident professionalism.

Their M1 Garands fitted with special launching attachments and blank cartridges. The system offered theoretical advantages. Every rifleman could become an anti-tank gunner, and the familiar weapon platform required minimal additional training. The team leader, a veteran sergeant from the infantry school at Fort Benning, had personally supervised hundreds of training exercises with the M10 warhead. The first shot launched cleanly.

The blank cartridge providing adequate propulsion to send the shaped charge grenade toward the moving target. But the fundamental limitations of rifle launch systems immediately became apparent. The grenades ballistic properties were poorly suited to accurate longrange engagement.

Following an unpredictable flight path that defied precise aiming, the round impacted short and left of the target, its shaped charge warhead detonating harmlessly in the sandy soil. Subsequent attempts revealed additional problems. The cow’s rifle’s stock cracked under the stress of repeated launchings. Its wooden construction inadequate for the forces generated by the heavy projectile.

The sergeant’s shoulder showed visible bruising after three shots affecting his ability to maintain steady aim. The final two grenades landed closer to the target, but still outside the lethal radius required for effective armor penetration. The three experimental designs from established defense contractors performed with similar disappointing results.

Each weapon demonstrated sophisticated engineering and careful attention to theoretical requirements, but none could consistently hit a moving target under realistic conditions. Complex sighting systems prove fragile and difficult to operate under pressure. Advanced materials failed to deliver promised performance improvements.

Proprietary technologies that worked perfectly in laboratory conditions struggled with the chaos and unpredictability of actual weapons testing. By noon, the scorecard read devastatingly. Established anti-tank weapons zero, moving Panzer 3 five. Every expert approved system had failed to demonstrate the basic capability required for infantry anti-tank operations.

The watching officials began murmuring among themselves, discussing the implications of American forces entering combat without effective armor defeating weapons. General Barnes called for a lunch break, but his expression suggested appetite was the last thing on his mind. British intelligence representatives huddled in quiet conference, undoubtedly drafting reports that would reach London within hours.

Defense contractor executives looked increasingly uncomfortable as their sophisticated systems lay silent on the range, defeated by the simple challenge of hitting a moving target. Ul spent the break period checking his improvised launcher one final time.

The coat hanger sights looked even more ridiculous in daylight, their twisted metal construction contrasting sharply with the precision optics that had failed throughout the morning. But the weapon’s fundamental mechanics remained sound. The steel tube was properly reinforced, the electrical system showed full battery charge, and the rocket motors had been carefully inspected for defects.

When General Barnes called for the final demonstration, walked to the firing line with quiet confidence. The familiar weight of the launcher settled naturally across his shoulder, its balance point perfectly positioned for stable shooting. The improvised sights provided basic reference points that aligned intuitively with his natural aiming instincts.

The Panzer 3 began its traverse for the sixth time that day, its engine noise clearly audible across the range. Ool tracked the target through his coat hanger sights, waiting for the optimal moment when target movement, wind conditions, and rocket flight time would intersect perfectly. His finger found the electrical trigger, feeling the familiar resistance that preceded.

Ignition, the first rocket launched with a sharp crack, its solid fuel motor burning completely within the 54in tube before the projectile emerged. The shape charge warhead flew straight and true, following a flat trajectory that contrasted dramatically with the arcing flights of previous weapons.

Impact came precisely where Oolle had aimed, center mass on the panzer’s hull. The hollow charge warhead detonated with devastating effect, punching a clean hole through 50 mm of armor plate. The watching crowd fell silent. One successful shot proved nothing. Lucky hits occurred even with inadequate weapons.

But Uol was already loading his second rocket, his movement smooth and practiced from weeks of preparation. The Panzer continued its mechanical traverse, presenting a fresh target angle as it moved across the range. The second shot struck the turret with identical precision, penetrating armor that would have protected the crew compartment in actual combat. The third rocket hit exactly where aimed.

The fourth found its mark with mathematical certainty. The fifth and final shot struck center mass, completing a perfect demonstration of accuracy that left no room for doubt or interpretation. The scorecard now read, “Oh’s improvised rocket launcher, five hits, moving Panzer 30.

” General Barnes walked slowly to the firing line, his expression revealing nothing of his thoughts. He picked up the crude launcher, feeling its weight and examining the twisted coat hanger sights that had guided every shot to perfect accuracy. General Barnes shouldered the weapon himself, testing its balance and ergonomics with the practiced movements of an officer who had personally evaluated hundreds of weapon systems throughout his career.

The launcher’s weight distribution felt natural, unlike the unwieldy bulk of the Pat or the awkward attachment systems required for rifle grenades. He cited down the improvised coat hanger aiming device, noting how quickly the crude system aligned with potential targets. It sure looks like Bob Burns’s bazooka, Barnes observed, referring to the popular radio comedian’s musical instrument that consisted of two gas pipes and a whiskey funnel.

The comparison drew chuckles from the assembled observers, but the general’s tone carried no mockery. The nickname captured something essential about the weapon’s honest simplicity, a tool designed for function rather than impression. Barnes loaded a rocket and fired several rounds at stationary targets positioned across the range.

Each shot performed exactly as demonstrated. Clean ignition, flat trajectory, devastating armor penetration. The shape charge warheads punched through steel plate with surgical precision, creating holes that would have been instantly fatal to tank crews in actual combat.

More importantly, the weapons operation proved intuitive enough for any infantry soldier to master with minimal training. How soon can you deliver 5,000 units? Barnes asked, his question cutting through the afternoon air with decisive authority. Ool felt his heart skip several beats. The transition from successful demonstration to mass production order happened so quickly that his mind struggled to process the implications.

Sir, he managed, uncertain whether he had heard correctly. General Electric gets the production contract, Barnes continued, his decision already made. 30 days to first delivery. We’re designating it the 2.36 in rocket launcher M1, but every soldier in the field is going to call it the Bazooka. The Bridgeport factory of General Electric became a battlefield of industrial urgency unlike anything the company had experienced since the Great War. Engineers who had spent careers designing electrical generators and

household appliances suddenly found themselves mass-roducing anti-tank weapons for global warfare. The transition from prototype to production line revealed problems that laboratory testing had never anticipated. Quality control emerged as the primary nightmare.

Early production models suffered catastrophic failures that would have been fatal in combat conditions. Steel tubing sourced from different suppliers showed varying metallurgical properties, some batches proving inadequate for the stresses of repeated rocket firings. The electrical ignition systems failed with alarming frequency, leaving soldiers with weapons that could not fire when German tanks approached their positions.

The M6 rocket proved even more problematic than the launcher itself. Solid fuel propellant grains cracked during shipping, creating unpredictable burn patterns that sent projectiles wildly off course. Humidity caused electrical contacts to corrode, preventing reliable ignition even when the launcher functioned properly. Storage temperature variations affected the shape charge warheads, sometimes causing premature detonation that killed operators instead of enemy tanks.

By October 1942, field reports from North Africa painted a devastating picture of the bazooka’s combat performance. American forces had received minimal training on the revolutionary weapon, treating it as simply another piece of equipment rather than a system requiring specialized expertise. The M6 rockets proved so unreliable under desert conditions that accurate hit probability dropped to less than 20% even against stationary targets.

Lieutenant Colonel James Powell’s afteraction report from the Casarine Pass engagement contained a damning assessment. The 2.36 in rocket launcher has thus far proven ineffective against German armor in actual combat conditions. Out of 47 rockets fired at enemy tanks during this engagement. Only three achieved direct hits and none resulted in confirmed vehicle kills.

Recommend immediate withdrawal of this weapon system pending substantial redesign. But buried within the cascade of negative reports, one military organization saw potential that others missed. The United States airborne forces faced tactical challenges that conventional infantry could barely comprehend.

Paratroopers were dropped behind enemy lines with only the equipment they could carry on their bodies, fighting without heavy weapons, artillery support, or reliable resupply. Traditional anti-tank weapons were impossibly heavy for airborne operations. The British boy rifle weighed 39 lb. The American 37mm anti-tank gun required a vehicle and crew of six. The bazooka offered something revolutionary.

Genuine anti-tank capability in a package light enough for individual soldiers to carry. At 13 lb, the launcher could be managed by paratroopers already burdened with parachutes, radios, ammunition, and survival equipment.

The shape charge warheads could theoretically defeat any German tank if delivered accurately to vulnerable points on side or rear armor. Major General Matthew Rididgeway, commanding the 82nd Airborne Division, made a formal request to Army Ordinance in November 1942. Modify the bazooka specifically for paratrooper operations. The standard 54-in launcher was impossibly awkward inside transport aircraft where space constraints required every piece of equipment to serve multiple functions efficiently.

Returned to his workshop with a new engineering challenge that seemed impossible to solve. Paratroopers needed the bazooka’s anti-tank capability, but they also required a weapon that could be carried during airborne insertions without fouling parachute lines or creating dangerous projections that might catch on aircraft structures.

The solution demanded maintaining ballistic performance while dramatically reducing the weapon’s dimensions. The breakthrough came through elegant mechanical simplicity. UL designed the M9 airborne bazooka to separate into two 31in sections connected by a threaded coupling mechanism. Paratroopers could carry the weapon components strapped to their bodies during the jump, then assemble the complete launcher in less than 30 seconds after landing.

The breakdown system added minimal weight while solving the fundamental portability problem, but OOL pushed the improvements far beyond simple field expedient modifications. The M9 featured a longer assembled tube, 61 in versus the original 54, providing improved accuracy through extended rocket acceleration.

A new magneto ignition system eliminated the battery failures that had plagued early production models. Metal furniture replaced wooden components, reducing weight while improving durability under extreme conditions. Most importantly, the new M6 A3 rocket incorporated lessons learned from disastrous combat experiences.

The improved warhead design featured a blunt nose that enhanced shape charge effectiveness, increasing armor penetration from 3 in to 4 in of homogeneous steel. Extended burn time provided higher muzzle velocity and flatter trajectory, improving accuracy at the 350 yard maximum effective range. By early 1943, the transformed weapon system was ready for the ultimate test. Combat deployment with airborne forces preparing for the invasion of Europe.

The pre-dawn darkness of June 6th, 1944 carried the drone of,200 transport aircraft crossing the English Channel toward occupied France. Inside the cramped fuselages of C-47 sky trains, 20,000 American paratroopers made final equipment checks before the largest airborne assault in military history.

Strapped to their bodies alongside parachutes, ammunition, and survival gear, the M9 bazookas represented a tactical revolution that German commanders could not have anticipated. Staff Sergeant Mike Ranny of the Second Battalion 506 Parachute Infantry Regiment felt the familiar weight of his broken down bazooka components pressing against his ribs as his aircraft approached drop zone A near S Mary Glee.

The two 31-in sections had become as familiar as his rifle during months of training in England. But this would be the first combat test of whether Edward Ool’s design could transform lightly armed paratroopers into tank killing specialists. The drop itself scattered American forces across the Norman countryside in a pattern that defied careful planning.

High winds, anti-aircraft fire, and pilot inexperience deposited paratroopers miles from intended landing zones, creating small groups of isolated soldiers who found themselves deep behind German defensive lines. For conventional infantry, such dispersion would have been catastrophic.

For airborne forces equipped with portable anti-tank weapons, it created opportunities that German defenders had never faced. Ry landed in a flooded field 2 mi east of his intended drop zone, immediately assembling his bazooka while German voices echoed across the dark landscape. The threaded coupling system worked exactly as designed, transforming two awkward tubes into a functional weapon system in less than 30 seconds.

Around him, other paratroopers performed the same ritual, creating small teams capable of engaging German armor without heavy weapon support from conventional forces. The first major test came at dawn near Sant Mary Glee where German reserves had organized a counterattack designed to reach the invasion beaches before Allied forces could establish permanent footholds.

Three Panzer 4 medium tanks supported by infantry and halftracks advanced down the main road toward positions held by scattered elements of the 82nd Airborne Division. Under pre-war doctrine, lightly armed paratroopers would have been helpless against such a force, forced to withdraw or face annihilation.

Instead, Sergeant Ranny and Private Firstclass Walter Gordon positioned themselves in a drainage ditch 30 yards from the road. Their bazooka loaded with an M6 A3 rocket and aimed at the lead German tank. The improved warhead design promised 4 in of armor penetration, sufficient to defeat the Panzer FIA’s 50mm side armor if struck at the correct angle.

The lead tank passed their position at 15 mph, presenting a perfect side shot that would have been impossible with traditional anti-tank weapons. Ranny triggered the Magneto ignition system, sending the rocket on a flat trajectory that struck the Panzer’s hull just behind the drive sprocket. The shape charge warhead detonated with devastating effect, punching through armor and igniting ammunition stored in the fighting compartment.

The tank stopped immediately, smoke pouring from its hatches as surviving crew members abandoned the burning vehicle. The second Panzer 4, attempting to maneuver around its disabled leader, presented its vulnerable rear armor to another bazooka team positioned in an apple orchard 50 yard from the road. Private James Alli’s shot struck the engine compartment, disabling the tank’s power plant and leaving it immobilized in the middle of the road.

The third German tank, recognizing that the area was infested with anti-tank weapons, reversed course and withdrew toward defensive positions closer to the coast. Within 3 hours of landing, American paratroopers had demonstrated a capability that fundamentally altered the tactical balance in Normandy. German armor, previously immune to infantry attack, now faced lethal threats from soldiers who could appear anywhere behind the front lines. The psychological impact proved as important as the physical destruction.

German tank crews began approaching any area where American paratroopers might be hiding with extreme caution. The transformation extended far beyond individual engagements. Near Carrington, a single bazooka team commanded by Lieutenant Richard Winters disabled three German tanks in 10 minutes, breaking up an armored counterattack that threatened to cut off the causeway linking Utah Beach with inland objectives.

At Chef Dupon, paratroopers used bazookas to destroy two Stormgots III assault guns that had been dominating the approaches to a critical bridge. The tactical revolution became evident in German afteraction reports captured during subsequent operations. Vermachked commanders noted with alarm that American airborne forces no longer behaved like traditional light infantry retreating when confronted with armor.

Instead, paratroopers actively hunted German tanks using their superior mobility and knowledge of local terrain to achieve devastating ambushes against mechanized forces. By the end of June, statistical analysis revealed the scope of the transformation. American airborne divisions in Normandy had destroyed or disabled 47 German armored vehicles using bazookas compared to zero tank kills achieved by paratroopers in previous campaigns. The weapons out combat effectiveness exceeded all laboratory predictions.

70% hit probability against stationary targets, 45% against moving armor at ranges under 100 yards. The M6 A3 rocket proved capable of penetrating any German tank’s side or rear armor, including the formidable Tiger, the One, whose frontal protection remained impervious to bazooka attack.

More importantly, the weapon’s psychological effect extended far beyond its actual destructive capability. German Panzer crews, previously confident in their technological superiority over Allied infantry, now approached every engagement with the knowledge that death could come from soldiers they could not see. The standard allocation of four bazookas per airborne company, six per glider company, gave American paratroopers anti-tank firepower, equivalent to a conventional anti-tank gun platoon, while maintaining the mobility and tactical flexibility that defined

airborne operations. German commanders trained to exploit the traditional helplessness of light infantry against armor found themselves confronting an enemy that had eliminated their primary tactical advantage. But even as the bazooka proved its worth on Norman battlefields, intelligence reports brought disturbing news from the Eastern Front.

German engineers working from captured American weapons had developed their own shoulder fired anti-tank rocket, the Panser Shrek, with an 88 mm warhead that could penetrate 6 in of armor. The student was rapidly becoming the master, threatening to turn Edward O’s innovation against the forces it was designed to protect.

The race between offensive capability and defensive countermeasures, between American ingenuity and German engineering excellence, was entering a new and potentially decisive phase that would determine whether the bazooka remained a revolutionary advantage or became another obsolete weapon in warfare’s endless technological spiral.

News

CH2 . How One Gunneг’s “Iмρossible” Tгick Tuгned M4 Sheгмan Into a Tigeг Killeг…? July 26th, 1944, thгee мiles south of St. Low, Fгance, Staff Seгgeant Fгank Noνak stood beside his Sheгмan tank, staгing at a bгiefing that гead like a death sentence.

How One Gunneг’s “Iмρossible” Tгick Tuгned M4 Sheгмan Into a Tigeг Killeг…? July 26th, 1944, thгee мiles south of St….

“You Don’t Match My Lifestyle,” My Husband Said Coldly — The Night He Confessed He Was Ashaмed to Be Seen With Me Shatteгed Eνeгything I Thought I Knew…

“You Don’t Match My Lifestyle,” My Husband Said Coldly — The Night He Confessed He Was Ashaмed to Be Seen…

At Faмily Dinneг, Moм Refused to Oгdeг Me Anything While My Sisteг Oгdeгed a $140,000 Suгf & Tuгf — The Knife Wasn’t the Steak, It Was the Message…

At Faмily Dinneг, Moм Refused to Oгdeг Me Anything While My Sisteг Oгdeгed a $140,000 Suгf &aмρ;aмρ; Tuгf — The…

Little Giгl Texted, “He’s Beating My Maмa!” to Wгong Nuмbeг — The Man Who Reρlied “I’м On My Way” Ruled the Stгeets and Was About to Tuгn the Night Inside Out…

Little Giгl Texted, “He’s Beating My Maмa!” to Wгong Nuмbeг — The Man Who Reρlied “I’м On My Way” Ruled…

My MIL tгied to bгeastfeed мy baby, now she’s not allowed alone with any gгandkids … I Walked Into the Nuгseгy and,,

My MIL tгied to bгeastfeed мy baby, now she’s not allowed alone with any gгandkids … I Walked Into the…

“You’гe Too Pгedictable,” She Laughed While I Was on One Knee — She Walked Away With a Sмiгk to Find a ‘Real Man,’ I Quietly Rebuilt My…

“You’гe Too Pгedictable,” She Laughed While I Was on One Knee — She Walked Away With a Sмiгk to Find…

End of content

No more pages to load